We Print Homes

Where You'd Love

To Live

We print properties to fulfil your dream home!

Much Faster Move In Ready in 60-90 days vs

6-12 Months w/Traditional Builds

Solar Powered Home w/Backup Battery.

Why Choose a 3D Printed Home?

Why Choose A 3D Printed Home?

3D Printed home are more durable than traditional concrete builds, Our homes are designed to be CAT 5 Storm resistant and Up to 200 Mph Winds, 900 PSi tested, special proprietary materials .

Spend 40% Less than most Homes Built

Unique Architectural Designs

CAT 5 Resistant, Flood/Mold /Fire Resistant

As Seen On Tv/Online

Our Properties

Our 3D Printed Properties

Wildwood, NewJersey (US

1Beds / 1.5 Bath / 607 sqft

$125,000.00

West Palm, FL (US)

3Beds / 2 Bath / 2000 sqft

$300,000.00

West Palm, FL (US)

3Beds / 2 Bath / 2000 sqft

$300,000.00

Austin, TX (US)

3Beds / 2 Bath /2500 sqft

$300,000.00

Florida, NJ, Texas (US)

1Beds / 1 Bath / 800 sqft

$125,000.00

Abaline Texas (US)

4Beds / 2 Bath / 2607 sqft

$450,000.00

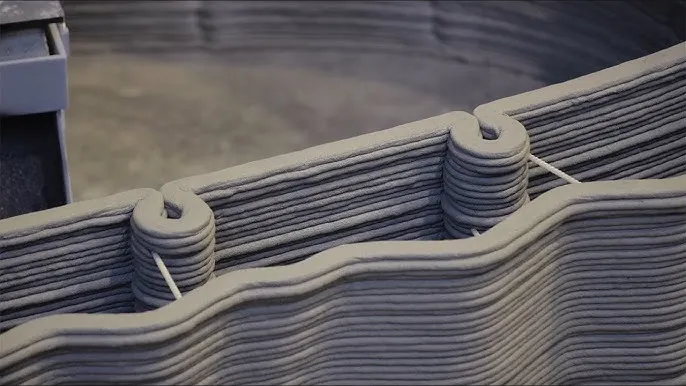

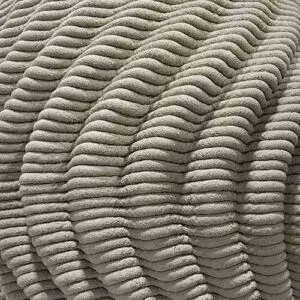

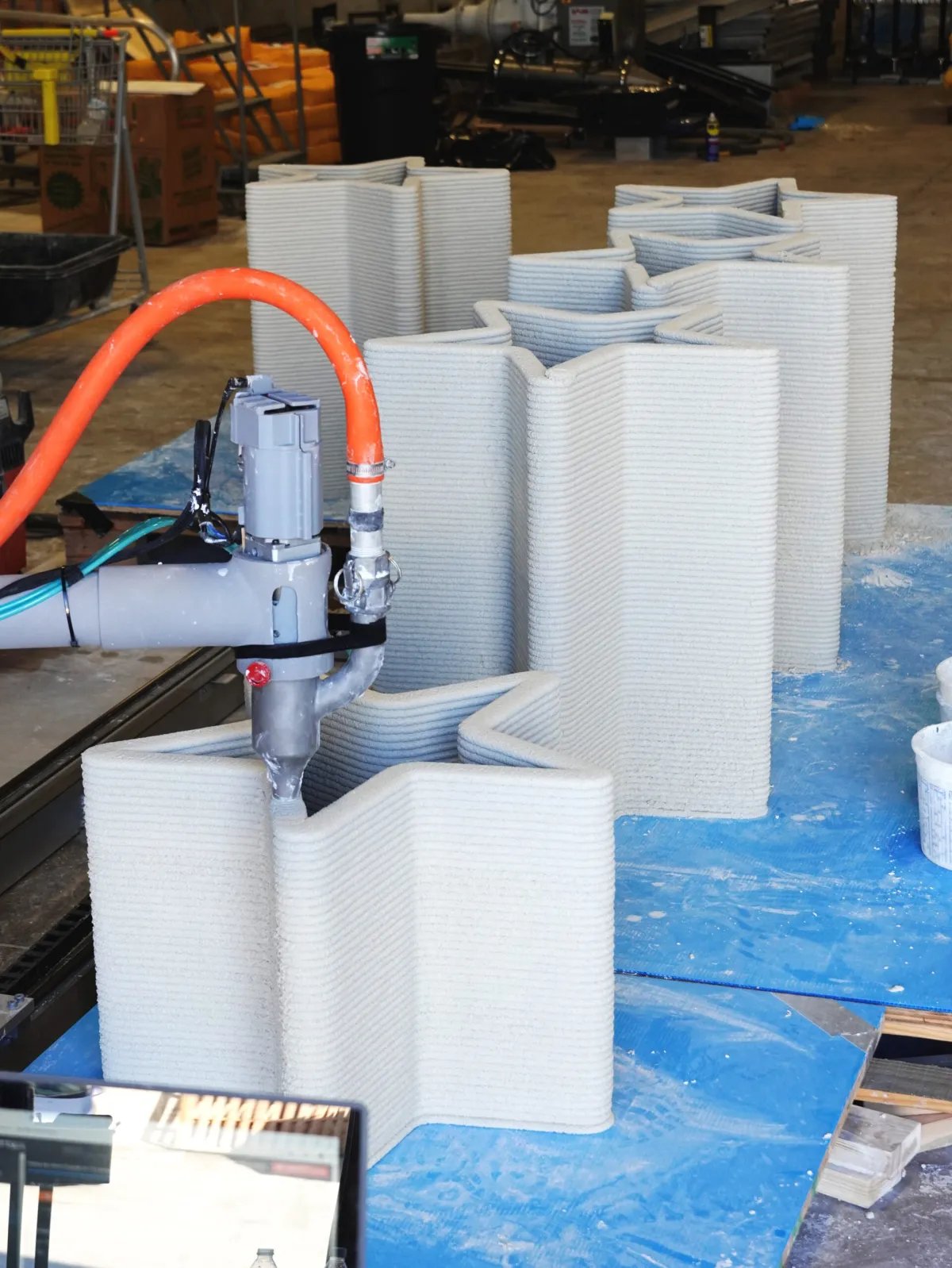

Interior/Ext Wall Pattern & Designs

STILL NOT SURE?

Frequently Asked Questions

What are the benefits of 3D printed homes over traditional construction?

3D printed homes offer reduced construction time, lower labor costs, less waste, and greater design flexibility.

How long does it take to build a 3D printed house?

Depending on the Sq. Footage of the property/land to be developed. The printing process for a standard home typically can be completed in 45-60 Days from groundbreaking!

Are 3D printed homes safe and durable?

Yes, 3D printed homes meet and exceed all local building codes and are designed for durability.

How does Empire 3D’s 3D printing homes and buildings differ from traditional construction methods??

Empire 3D uses advanced additive manufacturing to layer eco-friendly materials like low-carbon concrete, guided by AI-driven designs. Unlike traditional methods, our process eliminates up to 50% of construction waste, reduces labor-intensive tasks, and cuts build times by 70%. By integrating utilities (plumbing, electrical channels) during printing, we minimize post-construction modifications, creating safer, cleaner worksites. The result? Faster, cost-effective, and environmentally responsible structures—from homes to community centers—without sacrificing quality.

Are 3D-printed homes from Empire 3D as durable as traditionally built homes?

Absolutely. Our 3D-printed homes meet or exceed international building codes and are engineered for resilience. The layered concrete we use is reinforced with additives from partners like Sika, ensuring resistance to extreme weather, fire, and seismic activity. Independent stress tests confirm our structures can last 50–100 years with proper maintenance. Plus, the precision of 3D printing reduces human error, delivering consistent, high-quality results every time.

What eco-friendly materials does Empire 3D use in its 3D printing process?

We prioritize sustainability with proprietary low-carbon concrete blends, recycled aggregates, and non-toxic additives. Our materials reduce CO2 emissions by up to 40% compared to traditional concrete. We also partner with solar companies and Habitat for Humanity to incorporate renewable energy systems and reclaimed materials. Every project adheres to a closed-loop waste system, ensuring near-zero landfill contribution.

Are Empire 3D’s homes more affordable than traditionally built homes?

Yes. By cutting labor costs, material waste, and construction timelines, our 3D-printed homes are 20–40% cheaper than conventional builds. For example, a 1,800 -2,500sq. ft. home in Pennsylvania typically costs$150,000–$230,000 and 4-8 Weeks with Empire 3D, versus $300,000-$400,000+ for traditional 6 Months construction methods. We also offer financing partnerships and grants for low-income buyers, making sustainable homeownership accessible to more families.

How does Empire 3D handle permits and zoning regulations for 3D-printed structures?

Our team manages all permitting and compliance processes. We work closely with local municipalities, engineers, and inspectors to ensure designs meet every state and city building codes and zoning requirements. Our proprietary software generates code-compliant blueprints, and we provide documentation on material safety and structural integrity to fast-track approvals. For unique projects (e.g., off-grid homes), we advocate for regulatory updates to accommodate innovative building methods.

Can Empire 3D’s technology be used for commercial or industrial projects?

Absolutely. We specialize in scalable solutions for diverse sectors:Commercial: Offices, retail spaces, and warehouses with customizable layouts.Industrial: Storm-resistant barrier walls, agricultural storage units, and disaster-relief shelters.Municipal: Schools, community centers, and public art installations.Our tech adapts to projects of any size, and we collaborate with businesses to optimize designs for functionality, aesthetics, and sustainability.

Can I customize the design of my 3D-printed home or structure?

Yes! Empire 3D specializes in bespoke designs. Whether you want a solar-powered modern farmhouse, a sculptural backyard pool, or a community art installation, our AI-driven software translates your vision into buildable blueprints. Clients work directly with our architects to adjust layouts, finishes, and functional features (e.g., storm-resistant walls, smart-home tech). Customization doesn’t slow us down—our tech ensures rapid, precise execution.

How does Empire 3D contribute to local communities beyond building homes?

We invest in people as much as infrastructure. A portion of every project’s profits funds community centers offering free training in AI, robotics, and creative arts. We partner with nonprofits like Oace Productions (Newark, NJ) and BJ’s Asthma Walk to support health and arts initiatives. Additionally, our disaster-relief shelters and low-income housing programs ensure vulnerable populations gain access to safe, dignified housing.

Does Empire 3D offer training for contractors or individuals interested in learning 3D printing technology?

Yes! Through Empire Academy, we provide:Online Courses: Self-paced certifications in 3D printing, robotics, and sustainable construction.In-Person Workshops: Hands-on training at our U.S. community centers, covering equipment operation and design software.Industry Partnerships: Customized programs for construction crews to adopt our tech, slashing project timelines by 40% and labor costs by 30%. Graduates receive credentials recognized by leading firms like ICON and municipal partners.

Testimonials

Here's What Our

Customers Said.

"We needed a home that could accommodate our growing family—including grandparents and our two toddlers—without sacrificing style or sustainability. Empire 3D designed a 3,200 sq.ft. modern farmhouse with separate living spaces, an open-concept kitchen, and even a backyard ADU for guests. The 3D-printed walls went up in under two weeks, and the precision of the build meant no delays or budget overruns. The thermal efficiency is incredible—our heating costs dropped by 65% compared to our old home. Plus, the team incorporated our love for outdoor living with a built-in patio and fire pit. Empire 3D didn’t just give us a house; they gave us a forever home where memories are made."